Ultra Mag Series | Batch Control Systems (Electric)

Ultra Mag Series

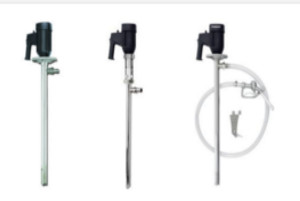

Standard’s Sanitary Batch Control System engineered for bulk, precision dosing and filling operations from drums, Tote® tanks and kettles – virtually hands-free. This system utilizes a non-invasive Full Bore Magmeter for flow / volume measurement. Simply dial in desired volume, press enter, and the Sanitary Batch Control delivers a preset volume of material within .05% accuracy. The system is an excellent solution for conductive food products, pharmaceuticals, and cosmetic materials.

Common Applications

- Lotions

- Shampoo

- Chocolate

- Pie Fillings

- Juice Concentrates

- Brine

- Pharmaceuticals

- Tomato Paste

Features

- 3A Certification

- Large Graphic Display

- Tri-clamp® Fittings

- Low Shear Design

- Non-Invasive Measurement

- Easy To Clean Design

- Multi-language Display

- Standard Or Metric Units Of Measure

- Measures Volume

Technical Data

| Design: | Progressive Cavity / Positive Displacement |

| Immersion Length: | 39” (1000 mm) |

| Wetted Components: | 316SS & PTFE |

| Pump Finish: | 32 Ra |

| Motor Drive: | TEFC (IP54), Variable Speed |

| Discharge Size: | 1.5" (38 mm) |

| Viscosity Range: | |

| P/N: 8300 (110v), 8301 (220v) P/N: 8313 (110v), 8314 (220v) |

1-10,000 cps (mPAS) 10,000-25,000 cps (mPAS) |

| Max. Discharge Pressure: | |

| P/N:8300 (110v), 8301 (220v) P/N: 8313 (110v), 8314 (220v) |

43 psi (3 bar) based on water 87 psi (6 bar) based on water |

| Max. Flow Rate: | |

| P/N: 8300 (110v), 8301 (220v) P/N: 8313 (110v), 8314 (220v) |

10 GPM (30,2 LPM) based on water 3 GPM (11,3 LPM) based on water |

| Duty Cycle: | Intermittent (30 Min. Intervals) |

| System Weight: | 54 lbs (24 Kg) |

| Max. Temperature: | 212° F (100° C) |

| Max. Solid Size: | .25" (6 mm) |

| Mechanical Pump Seal: | SiC / Viton® / SiC |

| Metering Principle: | Full Bore Mag Flow Meter |

| Check Valve: | 316 Stainless Steel |

| System Accuracy: | +/– 0.2% of reading (+/–0.5% Repeatability) |

| Conductivity: | System requires 5 micro-semans (µS/cm) of conductivity |

| Pump and meter is constructed with FDA compliant materials; however, the system does not have FDA certification. | |

| ®Viton is a registered trademark of DuPont Dow Elastomers. | |

Model Number

| Package P/N | Motor/ Voltage | Wetted Parts | Max Viscosity CPS (mPAS) | Immersion Legnth |

| Ultra Mag Batch Control System | ||||

| 8300 | TEFC / 110-120V | SS316, Teflon, SiC | 10,000 | 39" (1000 mm) |

| 8301 | TEFC / 220-240V | SS316, Teflon, SiC | 10,000 | 39" (1000 mm) |

| 8313 | TEFC / 110-120V | SS316, Teflon, SiC | 25,000 | 44" (1120 mm) |

| 8314 | TEFC / 220-240V | SS316, Teflon, SiC | 25,000 | 44" (1120 mm) |

| 8300BL | TEFC / 110-120V | SS316, Teflon, SiC | 10,000 | 39" (1000 mm) |

| 8301BL | TEFC / 220-240V | SS316, Teflon, SiC | 10,000 | 39" (1000 mm) |

| 8313BL | TEFC / 110-120V | SS316, Teflon, SiC | 25,000 | 44" (1120 mm) |

| 8314BL | TEFC / 220-240V | SS316, Teflon, SiC | 25,000 | 44" (1120 mm) |

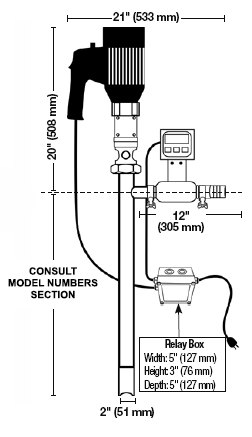

Dimension