Batch Control Systems | Low Viscosity (Air)

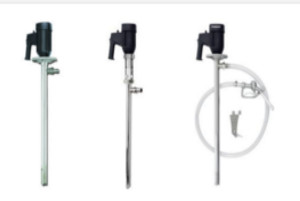

STANDARD’s Batch Control System (BCS) is engineered to control, measure and dispense preset volumes of liquid from drums, IBC’s, plating tanks or any large storage vessel. The air systems are ideal for high frequency, continuous duty applications. The BCS can be used in an industry where batching, chemical packaging or dilution is required to be accurate and efficient. Simply dial in the desired volume, press ENTER and the BCS delivers a preset volume of liquid virtually hands-free.

Common Applications

- Chemical Packaging

- Water Treatment Chemicals

- Chemistry For Plating Tanks

- Chemical Delivery

Features

- Turbine Paddle Wheel Design

- Measures: Gallons, Liters, Cubic Meters

- Resettable Totalizer

- User Friendly “In Field” Calibration

- 7 Pre-Set Batches

- PP & PVDF Materials of Construction Relay Output Signal

Technical Data

| Available Wetted Parts: | Polypropylene, PVDF, Hastelloy C, Ceramic & Halar |

| Motor Drive: | Open Drip Proof (IP44) or TEFC (IP54) (110–120V / 220–240V) |

| Discharge Fitting: | 1" (25 mm) Hose Barb |

| Pumping Principle: | Centrifugal / Sealless |

| Flow Range: | 4 GPM (15,2 LPM) - 27 GPM (102,2 LPM) |

| Maximum Viscosity: | 300 cps (mPas) |

| Immersion Length: | 27" (700 mm), 39" (1000 mm), 47" (1200 mm) 60" (1500 mm) or 72" (1800 mm) |

| Metering Principle: | Turbine (Paddle Wheel) |

| Accuracy: | +/- 0.61 % of Full Scale +/- 1% of Reading |

| Maximum Temperature: | Polypropylene 130º F (55º C) Stainless & PVDF 175º F (80º C) |