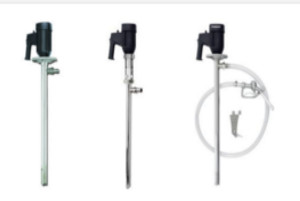

SP-8900 Sanitary Pump Series

Hygienic Design Enables Operators To Disassemble, Clean and Sanitize

Standard’s SP-8900 Series Sanitary Centrifugal Pumps offer the ideal solution for transferring Dairy Products, Pharmaceuticals, Juices, Concentrates, Beer, Wine, and Cosmetic Fragrances from barrels, kettles and Tote Tanks®. The SP-8900 Series pumps are 3A certified and incorporate a hygienic design that enables operators quickly to disassemble and sanitize. Designed for applications where maximum discharge pressure rate is required.

Common Applications

- Juices

- Concentrates

- Personal Care Products

- Pharmaceuticalss

- Beer

- Wine

- Cosmetic Fragrances

Pump Component Features

Features

- 3A Certified (TPV)

- Hygienic Design

- Easy to Clean

- Tri-Clamp Fittings

- Light Weight & Portable

- Variable Speed Electric & Air Motors

- Runs Dry

Technical Data

| Immersion Length: | 39" (1000 mm) Drums 47" (1200 mm) Totes, Tanks & Kettles |

| Wetted Components: | SS316L, PTFE & Buna |

| Discharge Size: | 1.5" (38 mm) Tri-Clamp Connection |

| Max. Viscosity: | 1,000 cps (mPAS)* |

| Max. Discharge Pressure: | 40 psi (2,8 bar) |

| Max. Flow Rate: | 35 GPM (132 LPM) |

| Pump Weight: | 11 lbs (5 kg) |

| Max. Temperature: | 175° F (80° C) |

| Pump is constructed with FDA compliant materials; however, the system does not have FDA certification. |

|

| Pump is intended for intermittent use when operating at maximum viscosity. | |

Flow Curves