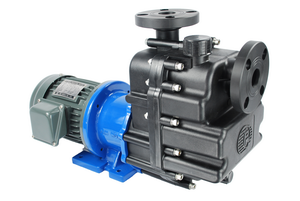

Magnetic Drive Pumps

Mag Drive pumps are sealless pumps that use the technology of a drive magnet and inner magnet connected to an impeller to move fluid thru the pump. The drive magnet and inner magnet are separated by a rear casing or housing, creating a seal-less containment. A Mag Drive Pump will prevent the leakage of fluid and even more importantly save you from the loss of potentially dangerous and costly liquids. With environmental concerns and EPA requirements more stringent than ever, seal-less pumps allow for zero fugitive emissions, allowing them to meet the necessary compliances. Due to their simplicity, mag drive pumps save maintenance time replacing seals and dealing with hazardous leaks. With only two moving parts, there is little chance for failure. Mag drive pumps are the answer for reliability and zero emissions. They are energy efficient and can circulate a variety of fluids including acids, caustics, and oils. Magnetic drive pumps (like most sealless pumps) have a higher capital cost than comparable centrifugal pumps, but offer reduced operating costs due to the lack of seal replacement, cleanup, waste, and downtime. They are particularly useful for transporting hazardous or expensive chemicals because there is no mechanical seal, eliminating the possibility of leakage or failure due to an obstruction.

Key Advantages of Magnetic Drive Pump

- Based on design of magnetic drive pumps there is extremely low risk of fluid and vapor emissions from being leaked. As a result, people working on or near the pump are not exposed to dangers from hazardous, corrosive, flammable and/or explosive fluids, and other toxic chemicals. In addition, expensive liquids are not wasted.Picture3

- Magnetic drive pumps are also reliable. When choosing a reliable brand, you will have confidence the pump will operate as specified.

- A pump of this type requires very little maintenance. The primary reason is that the design is actually quite simple. In fact, when used for normal operations it is common to see magnetic drive pumps go 10 years or longer before needing any kind of repair. Even then, repairs are often inexpensive.

- Another huge benefit associated with magnetic drive pumps is because of an easy coupling there is no need for an alignment of the pump or motor

How Magnetic Drive Pump Works?

A magnetic drive pump uses a balanced magnetic field to create the rotation of the fluid impeller. Unlike a traditional centrifugal pump which has a direct drive connection between impeller and motor, a mag-drive pump eliminates the direct drive mechanism and replaces it with a magnetic field. An outer magnetic bell housing is mounted on the end of the pump shaft. This outer bell is aligned on the outside of the rear casing. The pump impeller is connected to a smaller magnet assembly and rides on an internal shaft and bushing assembly. The smaller magnet assembly is mounted within the center of the magnetic field of the outer bell housing. Although these two magnet assemblies are separated by a fluid barrier, the magnetic fields are aligned. When the pump motor is started the outer bell housing begins to rotate. As the outer bell rotates, the rotating magnetic field effects the inner impeller magnet. As the two magnets begin to turn together, the impeller begins turning and displacing fluid.